With over 30 years of experience, our skilled mechanics and craftsmen know exactly what it takes to restore a bike to it’s original beauty and flawless function.

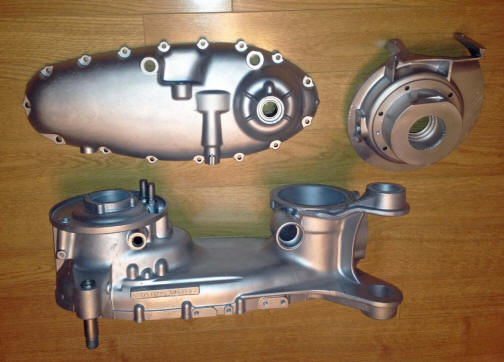

As a first step, the bike will be stripped down to bare metal. The original components that, in any way appear to be weak or damaged, are immediately replaced. Only the strongest parts are allowed to part of the restored bike. We then place the parts in our kiln and fire them at a very high temperature. Again, we remove any weak metal parts. This high temperature stage is an additional quality check. Bad parts are flagged easily after the firing. Even minor defects are revealed and thus culled. We know how important it is to only use first class components. Bad metal can result in engine failure and, even, danger. This step is exceedingly important. Although not initially apparent to our customers in Europe, America, Australia, etc., our tough standards here are a primary reason that we have so many loyal and repeat customers.

The next step is painting. Here, again, our skilled craftsmen have years of experience. Painting is completed in our specially fabricated paint room – a carefully controlled dust-free area with a waterfall curtain. The bare metal is covered, first, with a rust protection layer and dried. Then, a special powder is applied thickly to both sides of the metal. We only use powder from ICI Corporation that is specially formulated for this purpose. Working quickly and efficiently, our craftsmen coat the bike – before this layer becomes rock-hard. The powder has several purposes. It helps to prevent rust, fill out small dents and holes and, importantly, create a glassy-smooth surface. The powder is applied to both sides of the metal, in that most rust, in fact, starts from the inside. The powder layer also provides a vital base layer for the subsequent top-coats of paint. These top-coats are, in part, absorbed by the powder layer and this bond creates an integral and long-lasting coating.

At this point, we start the main paint layers. The paint that we use here is identical to the automobile paint used by car manufacturers. Your bike is painted on both the inside and outside – yet not on the frame. The last layer is our “2K” layer that provides the lustrous glow and scratch-free-surface. The scooter parts are then sent to the baking room. Using magnetic waves and high temperatures, the paint is cross-linked and cured. The result is a shiny and incredibly durable surface.

We use genuine, original OEM new parts imported from India, Italy, Germany….. That way, our quality is assured.

The bike is methodically assembled under the watchful eye of our senior mechanics. They also must pass the toughest test of all, the ruthlessly honest checks from our patriarch, who has been restoring scooters for over 40 years. Little escapes his scrutiny.

Once assembled, scooters are started and then road tested. The 100km road test is performed by independent drivers. They do not hesitate to point out defects, however minor – which are quickly repaired and retested.

New parts: front/rear brakes, kick start, drums, front axle, all bearings, seals, hub caps, tires, tubes, fuel tap/lever, front/rear lights, seat, all cables, all rubber parts, all electrical components, exhaust system, all electrical wires/switches and assemblies, locks with keys, speedometer, horn, emblems, shocks and suspensions, stainless steel protectors, carburetor (SPACO), cylinder and piston, piston rings, spark plug, 12V CDI, fly wheel, 12v regulator,…